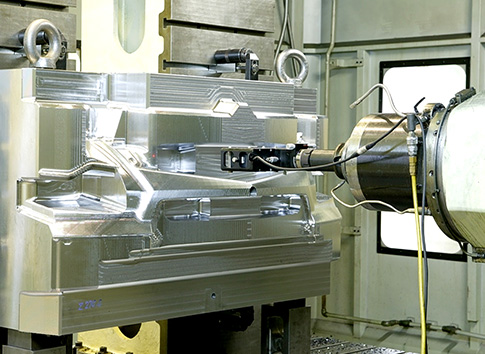

To achieve the high quality our customers demand, MEIKI developed 3-dimensional measuring device (patented) for surface process management. Our trial in house molding machines lineup varies from 350t to 4000t, thus MEIKI has reliable and high quality system management.

| Machine | Makino (controller FANUC 15M) |

|---|---|

| Measured material | Core slide |

| Measurement pitch | 80mm |

| Measurement time | 5min |

| Measurement points | 1476 points |

| Measurement result | reference measurement coordinate values (XY position is entered and Z value is requested) |

| Evaluation | Difference with the 3D data is displayed Difference with theoretical value (CAD data) 0.01mm – 0.05mm |

Because we pursue the quality and take full responsibility for of all mold make, we have established a prototype molding machine. Lineup range of machines is from 350t to 4000t and they are used for in house trials. It is also possible to make in house trial for heating and cooling, for gas injection molding and other special molding specifications.